发布日期:2017-11-24 查看:0

Internet of things want to go far, depends on the degree of development of sensors. Whether it's information collaboration, measurement, analysis, and control between machines, sensors are needed to gather information.

Who mastered the sensor, who will grasp the future of the Internet of things.

At the same time, China wants to gain a foothold in the Internet of things and even the industrial Internet of things, sensors are the most suitable entry point for china. The past experience of manufacturing and semiconductor industry will effectively help China to gain a foothold in the future of Internet of things.

If there is no sensor to detect the pressure, location, temperature and other important production data, Industrial Internet of Things (IIoT) will not have today's development. Basically, the development of Things and Consumer Internet of (IoT) is accompanied by the expansion of sensor market, while sensor technology innovation and R & D will also stimulate the potential and development of the Internet of things industry.

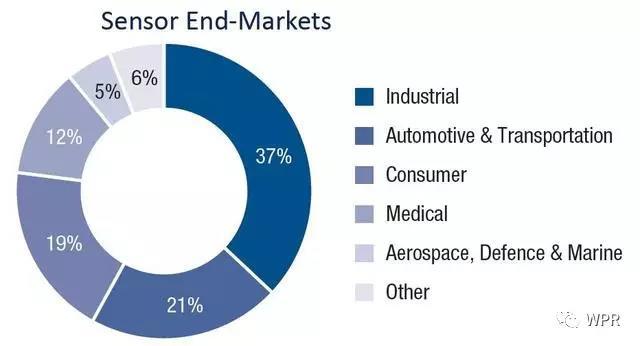

Sensors still dominate the industry, accounting for 31% of the market

The sensor used in the automation industry increasingly high proportion, such as automotive electronics, automatic drive of sensors are in high demand, accounting for 21% of the market demand for sensor; sensor medical industry also increased, they rely on sensor monitoring and medical diagnosis of patient health, currently accounts for the sensor market 12%. However, the largest proportion of the market is still the industrial sector, accounting for 31% of the total.

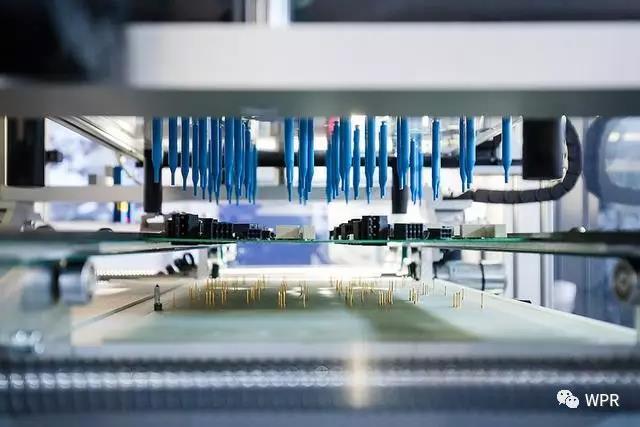

Industrial applications usually focus on producing high-end products rather than high production, so the demand for sensors tends to be reliable, precise and small in harsh working environments. As Machine-to-Machine (M2M) links become more and more sophisticated, the task of sensors also evolves from passive monitoring to proactive detection, preventive maintenance, asset management and data analysis to help increase production efficiency.

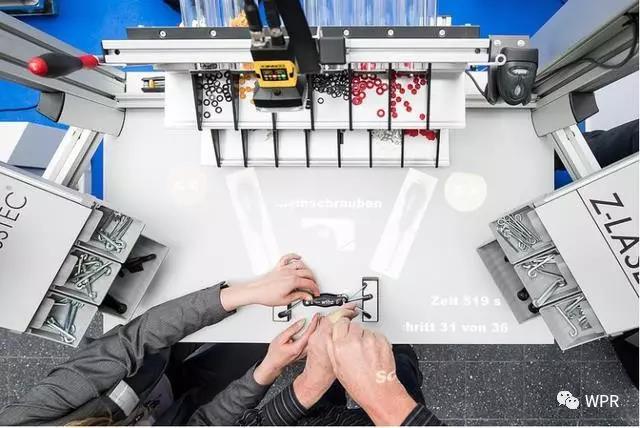

In the field of automated processes, processes such as process control, process safety, job management, and asset utilization require sensors to measure, analyze and control system settings. The integration of multiple sensing technologies and software analysis tools to promote productivity, reliability and safety of information dissemination will become faster and more accurate. Finally, the industry will usher in a work environment where costs are optimized and high-end products can be produced.

Now, in order to grasp this trend, the United States, Britain and the European companies are actively cooperate with the science and technology company, specializing in the acquisition of real-time data management, asset management and sensor equipment company, corporate mergers and acquisitions between the formation of cyclone in the sensor market, because this can not be certain entry barriers. Traditional sensor companies are also willing to cooperate with companies in new industrial blocks, and technology makers are jumping into the battle of sensors.

Such sensor market mergers and Acquisitions Trends, will be critical to let us guide more than now more interconnected, more automated world. In several major industries, such as manufacturing and Internet of things, with the increase of automation, the use of sensors will be more popular, such a high market demand and unlimited business prospects will attract more people to join the market.

Sensors help intelligent factory examples: use laser sensors to automatically detect liquids, saving a lot of time cost!

When the computer services and data are pushed up to the cloud, the structural evolution of the Internet of things will also be based on equipment, not only the cloud has intelligence, and even equipment should have a brain that can work independently. In the industry, there are many innovative ways to use sensors to manage production processes and optimize production efficiency.

Installed in large containers, bucket, bucket bin powder and bulk solids instant elevation measurement and volume measurement, quality measurement has always been one of the industry's troubles. To manage assets and processes, requires very accurate measurement results, but most of the time these substances owners must manually measure these data, despite the laser technology assistance, still must be completely stopped the process, spend a couple of hours to get results.

However, after introducing the 5708 scanner, the industry can do the measurements without interruption, even if the fly ash or low dielectric material, which is difficult to be measured by other technology, can also get the data through the sensor. The scanner can even simulate irregular surfaces of solid matter, provide minimal and maximum elevation, total volume, and a visual model of 3D.

On the other hand, long distance and wide range temperature control must also depend on sensors. The DTSX3000 optical fiber inspection technology designed by Yokogawa solves this problem. Traditional technologies rely on multiple surveillance cameras, thermocouples, resistance temperature detectors, or other temperature sensors, which are cumbersome to operate, install, or maintain. The sensor developed by Yokogawa is a space unit per meter, and can be used to measure the temperature up to fifty km along the optical fiber network.

Some sensor research and development, already faint with the shadow of the future world. For example, a Israel Corp has developed the world's first nano technology of electronic nose can smell, such as bombs, biological weapons and toxins can be detected by a security threat, and even the most trace elements. Dr. CEO Ricardo Osiroff of the company said, this can be called "nano sensor laboratory", from the gas, liquid and solid samples, to detect the chemical threats of different kinds, such as explosives, biological weapons, efficiency significantly beyond existing technology, is completely better than dogs or other animal drug.

The key to the development of the Internet of things lies in the cooperation among the machines, and the sensor is the heart of it

"Sensor chip high speed integration technology" can choose different characteristics of wireless sensor blocks, combined into a new sensor chip. For example the chip center combined motion sensor, capacitance sensor, signal processor, low power read Bluetooth wireless transmission, battery power management circuit, making the intelligent sensor chip, when the backpack backpack "fast sharp moves, which may be the climber fall Valley, immediately issued a distress signal to the specified object; the combination of deformation sensor chip center the resistance sensing signal read, RFID wireless transmission, electromagnetic wave energy capture circuit, making the smart chip bone plate, when bone plate injury healed completely, no deformation, will send a notice of the doctor can surgery to remove bone plate.

Foreign manufacturers mainly sensor technology into the industrial process, China can make this technology closer to life, transportation, medical, rescue, wearable devices are worth investing in the field. The key to the development of the Internet of things is collaboration and information transmission between machines, and sensors play an indispensable role in these machine networks and in the longer term interconnected world.